Table of Contents

DTF, or Direct to Film, is a relatively new printing technology that allows for high-quality, full-color, dark-color, and light-color printing of photos directly onto shirts and other apparel items including cotton, polyester, nylon, Converse, linen, leather, and blends. Compared to traditional methods such as screen printing or heat transfers, this method offers excellent results. This new technology is gaining popularity among small businesses and personal business owners.

With a fast turnaround time and no minimum order quantity, the DTF Printing Service is perfect for both small businesses and individuals looking to create custom apparel. If you’re interested in trying out DTF printing, this comprehensive guide will walk you through the step-by-step process, including the equipment you’ll need and the different stages of the process.

To start with DTF printing, you will need the following equipment and materials:

- Epson L1800 or L805 Printer: These printers are capable of printing high-quality designs onto the DTF film.

- DTF Film: This is a special film that is used to print the design.

- Powder: This powder is used to enhance the adhesion between the film and the garment.

- Heat Press: A heat press is needed to transfer the design from the film onto the garment.

- Oven: An oven is used to dry the garment after it has been printed.

Now that you have gathered all the necessary equipment and materials, it’s time to start the DTF printing process.

Overview of the Process

The process of DTF printing involves the transfer of designs using a heat press from a special film to the desired substrate. The film is printed with a specialized printer that uses white ink to create a base layer for the design. The design is then printed on top of the white layer using colored inks.

After the design is printed on the film, it is peeled from the backing and placed on the substrate. This process creates a durable, long-lasting print that is resistant to fading and peeling.

Step 1: Design Creation

Design creation is the first step in the DTF printing process. The design can be created using a variety of software, such as Adobe Illustrator, Photoshop, or even in PNG format. The design should be created with the end product in mind and be of high resolution to ensure a high-quality print. Once the design is created, it should be saved and prepared for the printing process.

Step 2: RIP Software for Print Command and Control Inks

To control the inks and print on the DTF printer, RIP (Raster Image Processor) software is used. This software allows for the precise control of ink placement and color. It is used to prepare the design for printing and send the print command to the printer. In this process, the Epson L1800 or L805 printer is commonly used due to its ability to handle DTF printing.

Step 3: Print on DTF Film Paper

As soon as the design is prepared and the RIP software is used to control the inks, the design is printed onto the DTF film paper. This paper is specially designed to work with the DTF printing process and allows for a high-quality print with vibrant colors. The printer uses a white ink base layer and then prints the design on top of it. A4 and A3 paper are used to print the design most often. And A3 paper allows printing larger format images onto larger items.

Step 4: Powder Apply on Printed FILM Paper

Once the design is printed on the DTF film paper, a layer of powder is applied to the surface of the paper. You must ensure that you cover the film paper completely with the DTF powder. This powder is designed to stick to the ink and act as a bonding agent between the film paper and the transfer sheet.

Step 5: Curing the Film Paper

After the powder is applied, the film paper is cured using a heat gun or curing machine. In this process, the powder is fully melted and bonded with the ink (like an adhesive sticker), creating a solid layer that can be transferred to the transfer sheet.

Step 6: Heat Press

Now that the film is ready, it’s time to print it onto the garment (fabric or product). Place the garment on the heat press and lay the film on top of it. Apply pressure and heat to transfer the design from the film onto the garment. The heat press should be set to the appropriate temperature and time, which may vary depending on the fabric and the specific heat press being used. Don’t forget to put silicon paper on top so the film won’t stick to the heat map.

Step 7: Final Touches

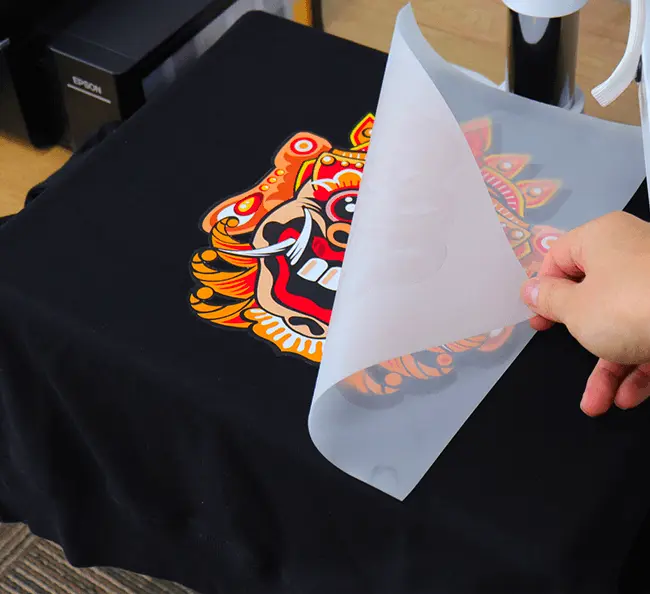

After the design has been transferred, it’s time to peel off the film. The film should be peeled off while it’s still warm, and the design should be left to cool before handling it. Once the design is cooled, it can be inspected for quality and durability. Your DTF-printed garment is now ready to wear or sell!

Why Choose DTF Printing for Small Businesses?

As a small business owner, choosing the right printing method can be a daunting task. DTF printing, however, is an option worth considering due to its many benefits.

Low Cost

DTF printing is cost-effective. Small businesses that need to print low-quantity runs can benefit from this printing method, as the equipment and supplies required are relatively affordable. This makes it accessible for small businesses with limited budgets.

High Quality

DTF printing is a high-quality print produced. The white base layer ensures fine and clear details, which ensures vivid and accurate colors. Additionally, the heat press used in DTF printing transfers the design to the substrate with precision, ensuring that the final product is of excellent quality.

Versatility

DTF printing is versatile. It can be used on a wide range of substrates such as cotton, polyester, and more. This makes it an excellent choice for small businesses that need to print on different materials.

Conclusion:

DTF printing is an excellent option for small businesses and personal business owners looking to create high-quality, vibrant prints on dark or colored fabrics. While the process does require some specialized equipment and knowledge, it can be relatively easy to get started with the right tools and guidance. By following this comprehensive guide, you can be on your way to creating stunning DTF-printed garments in no time!

Tips and Considerations:

- Choose the right fabric: DTF printing works best on fabrics with a high polyester content, as they have a more receptive surface for the ink to adhere to. Fabrics with a high cotton content may not produce the same vibrant results.

- Experiment with settings: Different fabrics and printers may require different settings for the best results. Be sure to experiment with different temperatures, times, and other settings until you find the combination that works best for your specific setup.

- Proper storage: DTF film should be stored in a cool, dry place to prevent it from absorbing moisture, affecting the printing quality.

- Cost-effective: DTF printing can be a cost-effective option compared to other printing methods, as it allows for high-quality prints without the need for expensive screens or transfers.

DTF printing is an innovative and cost-effective method for creating high-quality, vibrant prints on dark or colored fabrics. With the right equipment and knowledge, small business and personal business owners can easily incorporate DTF printing into their workflow and offer unique and eye-catching products to their customers.

FAQs: Frequently Asked Questions

What materials can I print on using DTF printing?

- Printing on cotton, polyester, and blends

- Printing on dark and light fabrics

- Printing on hard surfaces like ceramics and plastics

What kind of equipment do I need to start DTF printing?

- A DTF printer

- Transfer film

- Heat press

- Computer and design software

Can I use DTF Printing for customized designs?

Yes, DTF Printing allows for flexibility in design and customization, making it a great option for small businesses.

Can I print multiple colors with DTF Printing?

Yes, DTF Printing allows for printing in multiple colors.

Is DTF printing suitable for printing high-resolution images?

DTF Printing can produce high-quality prints with sharp details and vibrant colors.

Can I wash garments printed with DTF Printing?

Yes, garments printed with DTF Printing are durable and can withstand washing and wear.